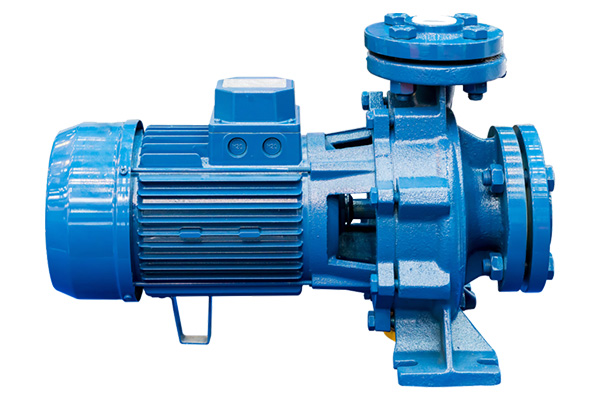

Absolutely, preventive maintenance is crucial for ensuring the longevity and efficiency of centrifugal pumps. Here’s a guide to creating a maintenance schedule for your centrifugal pump

Regular Inspection: Establish a routine schedule for inspecting your centrifugal pump. This can be weekly, bi-weekly, or monthly depending on the criticality of the pump and its usage. During inspections, check for leaks, unusual noises, vibrations, and any signs of wear or damage.

Lubrication: Lubricate bearings and other moving parts according to the manufacturer’s recommendations. Over time, lubrication can degrade, leading to increased friction and wear. Proper lubrication helps reduce friction and extend the life of pump components.

Alignment: Misalignment can cause excessive vibration and premature wear on bearings and seals. Regularly check and realign the pump and motor to ensure they are properly aligned according to manufacturer specifications.

Impeller Inspection: Inspect the impeller regularly for any signs of erosion, corrosion, or damage. A damaged impeller can lead to reduced pump efficiency and performance. If any damage is found, consider repairing or replacing the impeller promptly.

Seal Inspection and Replacement: Check the seals for wear and leakage. Replace seals as needed to prevent fluid leakage and contamination. Proper sealing is essential for maintaining pump efficiency and preventing damage to internal components.

Check Couplings: Inspect couplings for wear, misalignment, or damage. Replace worn or damaged couplings to ensure proper alignment and transmission of power between the pump and motor.

Monitor Motor Performance: Keep an eye on the motor performance parameters such as current draw, voltage, and temperature. Unusual fluctuations or deviations from normal operating conditions may indicate potential issues with the pump or motor.

Clean Pump and Surrounding Area: Regularly clean the pump and its surrounding area to prevent debris buildup, which can impede pump performance and lead to damage.

Review Operating Conditions: Periodically review the operating conditions of the pump, including flow rate, pressure, and fluid properties. Ensure that the pump is operating within its design limits to prevent overload and premature wear.

Training and Documentation: Ensure that personnel responsible for pump maintenance are properly trained in pump operation and maintenance procedures. Maintain comprehensive documentation of maintenance activities, including inspection reports, repair records, and parts replacements.

By following a proactive maintenance schedule and addressing issues promptly, you can extend the life of your centrifugal pump, minimize downtime, and reduce operating costs in the long run.

© 2023 Created with Royal Elementor Addons